Making your production plant more effective

Get the software solution that

improves your factory’s efficiency!

Solutions Within Tipteh IoT Platform

Take advantage of our wide range of

products to develop your perfect-fit solution.

WHY WE’RE THE RIGHT CHOICE

1

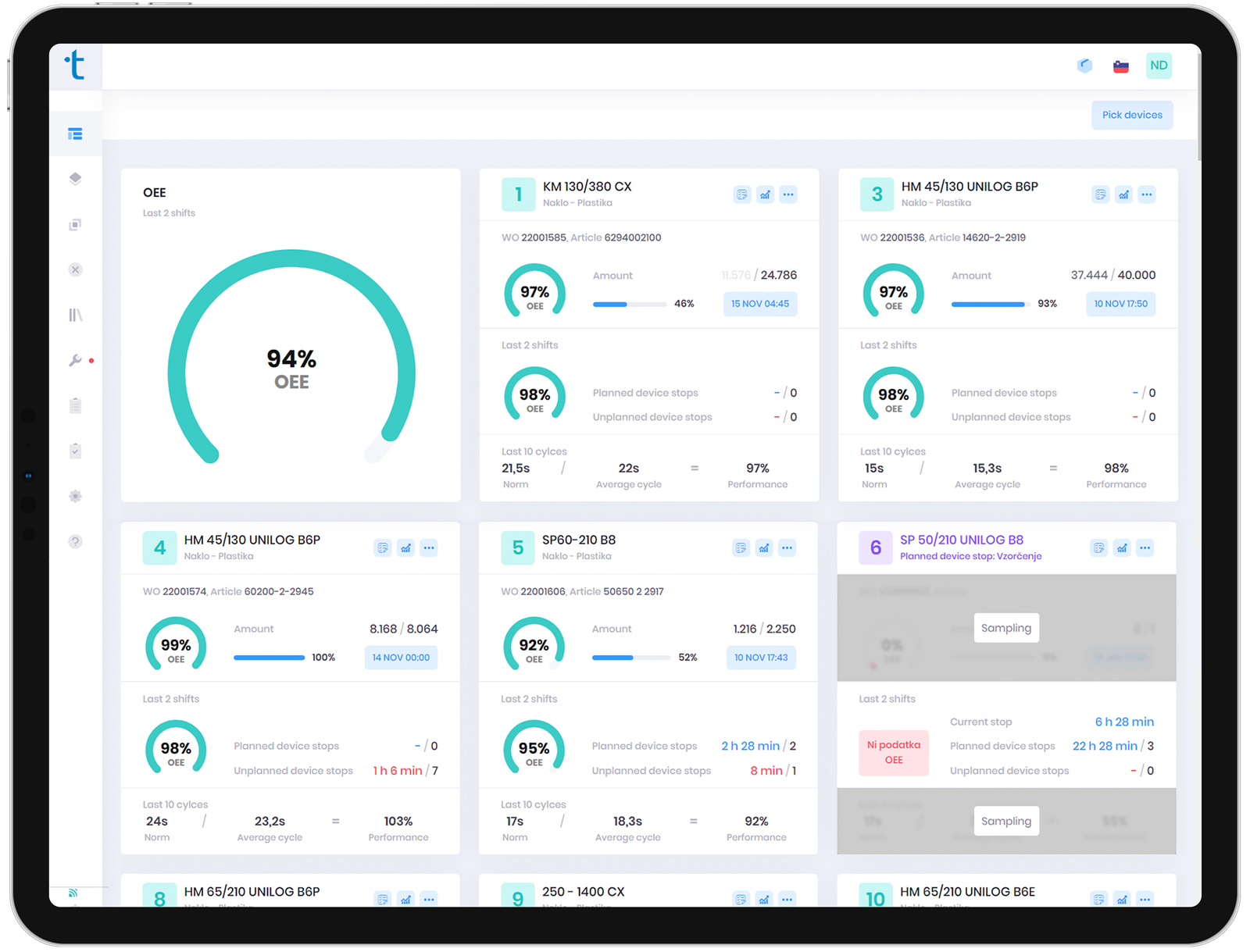

Your Machines In One Place

All of your machinery can be easily connected to a single dashboard where all of your data will be collected and displayed. Get information about how a Tipteh specialist can help you set up a connection between your machines and the software.

2

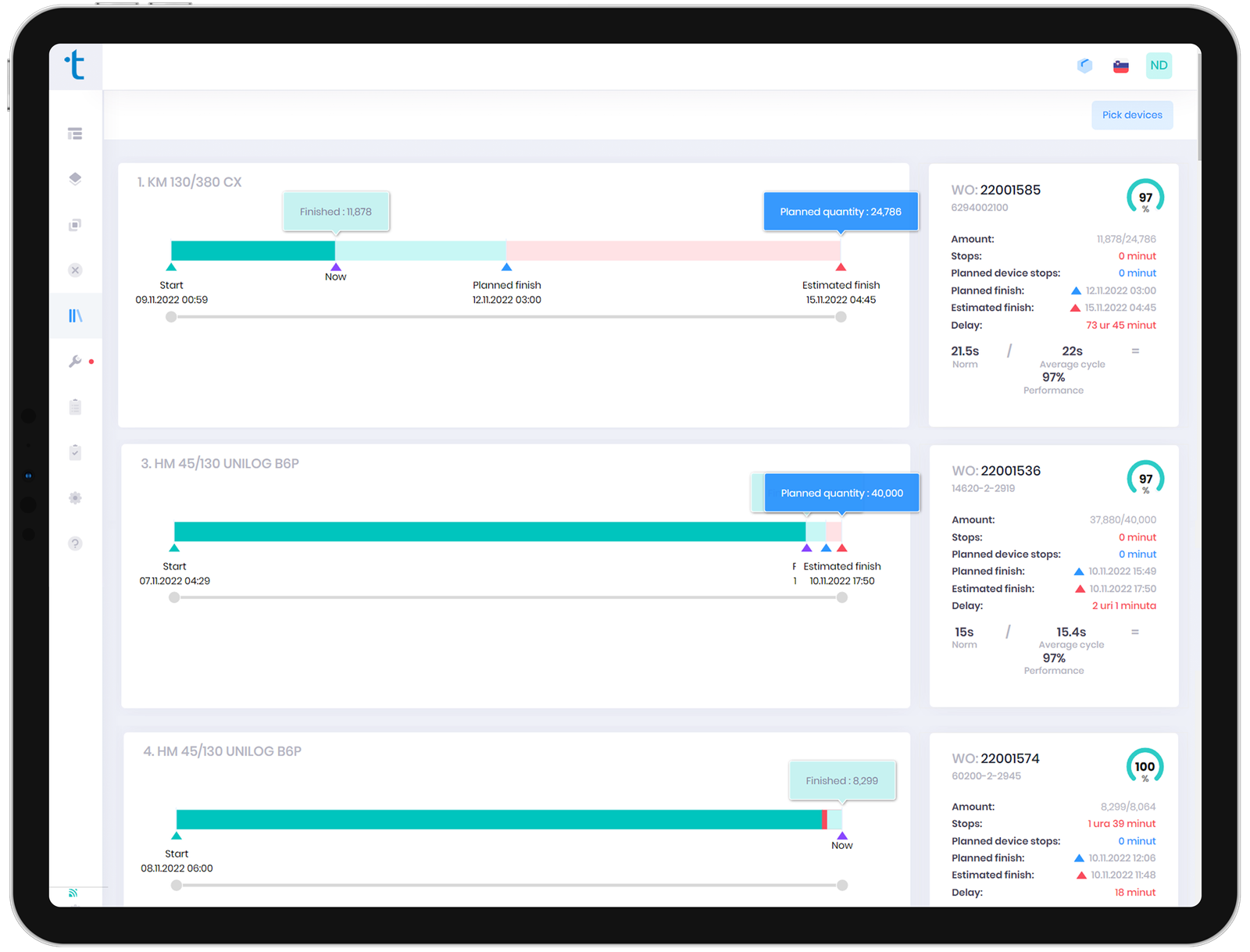

Have Your Work Orders Implemented Correctly

All of your work orders can be prepared, implemented and tracked through the software. See which work orders have been completed and which ones need to be optimized - all in a single place that is personalized for your production plant.

3

Our Software Increases Your Factory Efficiency

Through precise data collection and real-time reporting, you get a deeper look into how your factory truly functions and what sections can be improved. Analyze your production performance in different phases over custom time periods and optimize for improvement.

4

You Get An Expert Consultant On Your Side

Our Tipteh automation specialists are at your disposal as soon as you start using any of the software solutions! Get direct help from experts in the industry who have years of experience in automation in order to improve your overall factory performance.

What Do You

Want to Achieve?

Track and Increase OEE

Decrease Operations Cost

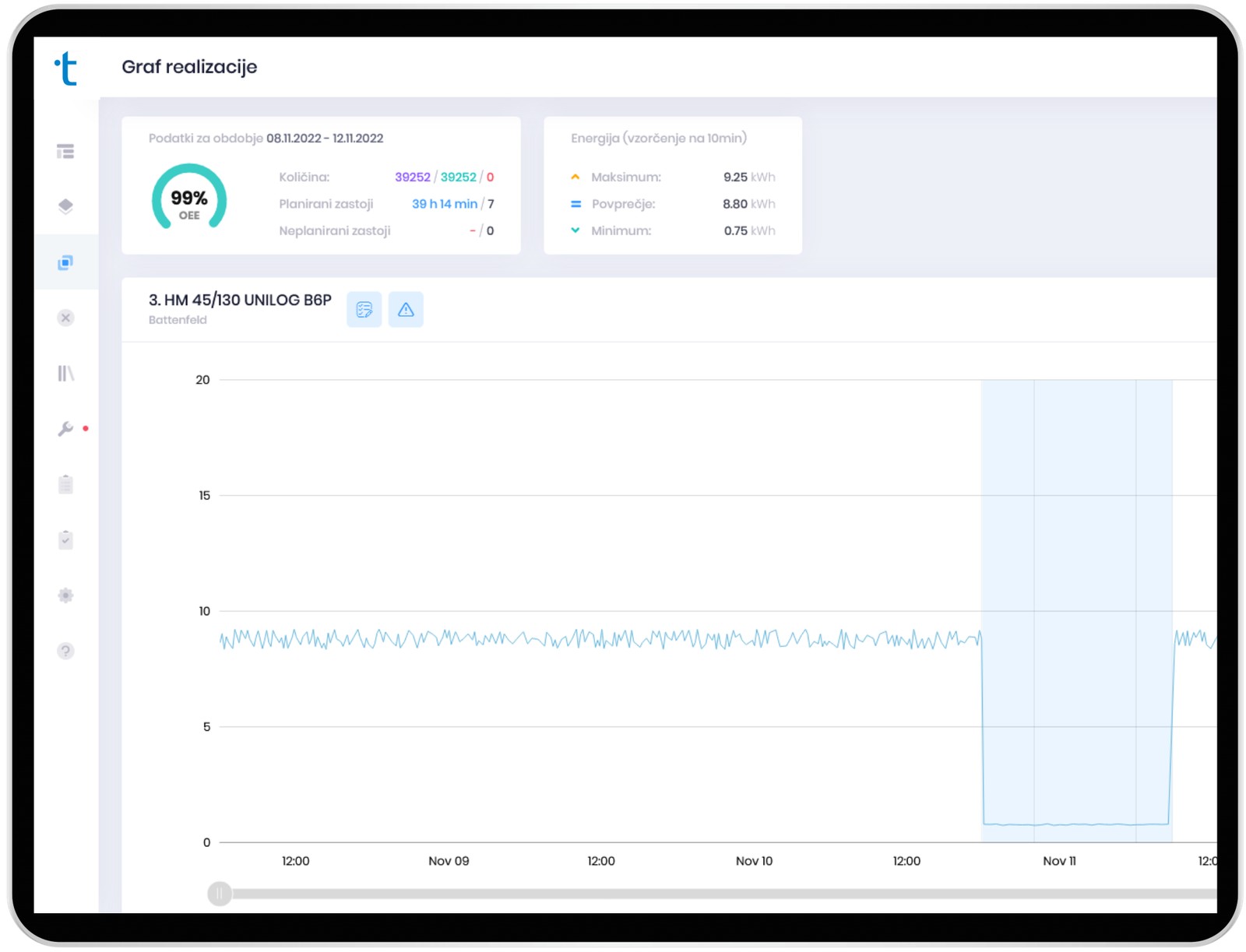

Save Energy

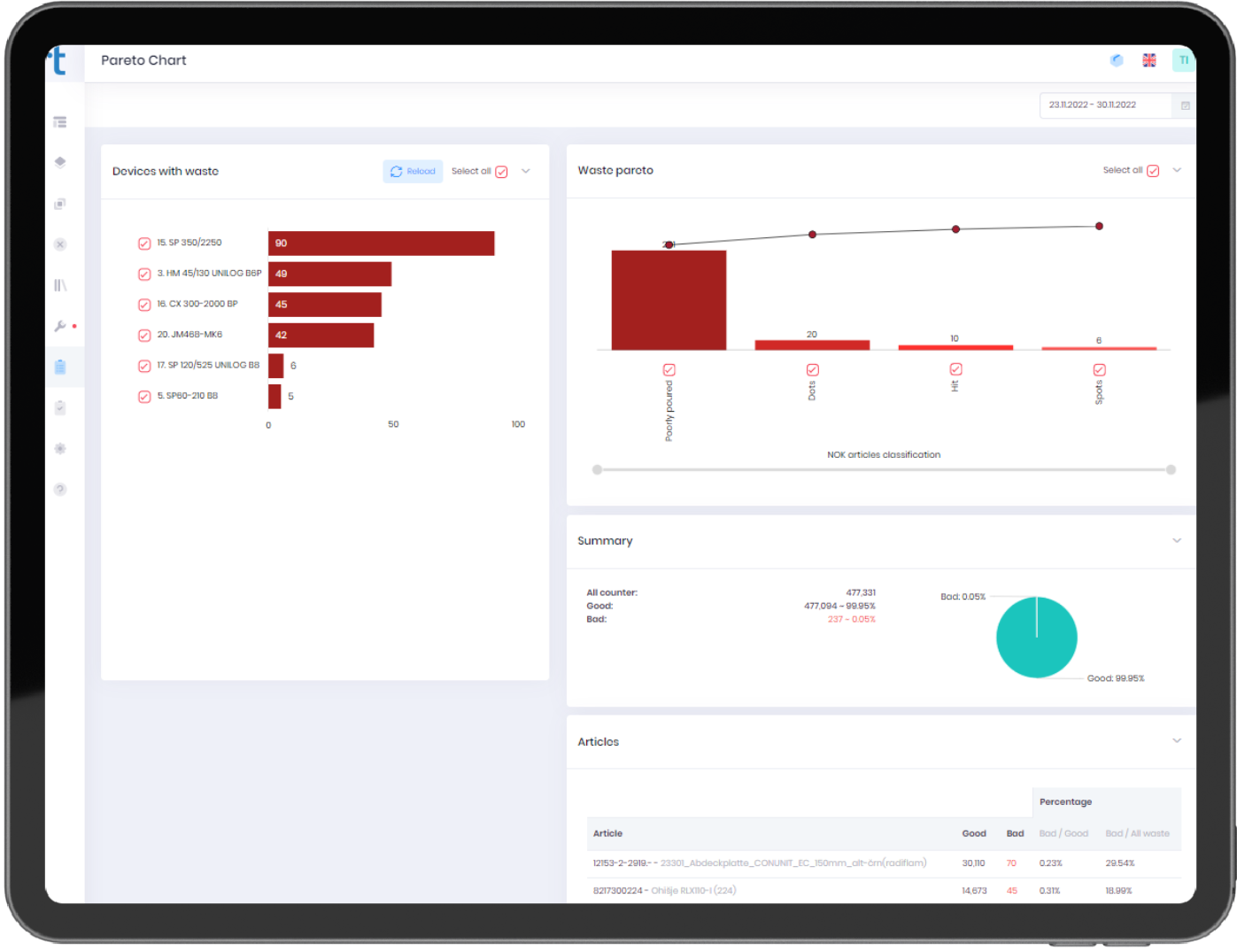

Reduce Waste

Get a Preview of Our IoT Platform

Our main goal is to help businesses overcome obstacles on their way to optimal performance. Reach out to one of our experts to get direct information regarding solving the issue you may be having.

Benefits for your production

65%

Faster reaction time

- Get direct feedback about each work order

- Track work order performance in a single dashboard

- Defect alerts are instant

90%

Reduction in reports generation

- Get data in real time from your production line

- All reports are easily exportable

- Automate your reports for different goals

11%

OEE increase

- Track where you’re wasting your resources

- Find out what steps of the production can be improved

- Learn more about your machine performance

60%

DECREASE IN HUMAN ERROR DURING PRODUCTION

- Inform your decision making in real time

- Get direct insights into your production line as the product goes through all the manufacturing stages

- Decrease possibility of interfering with the production process

25%

DECREASE IN UTILITY CONSUMPTION

- Gain insight into your utility consumption and optimize your savings

- Get a better understanding of your machine utility input

- Identify and address inefficiencies in real time

CHOOSE YOUR GOAL

A simple 6-week process will

get your new software fully set up!

Our team works diligently to make sure the software and all the connections are established correctly. Let us handle all the necessary steps and set up your software solution in less than a month!

Knowledge Base

10 Examples Of Green Manufacturing Practices

Calculating OEE – Formulas & Examples

How does improvement in OEE improve your manufacturing KPI

The Biggest Mistakes in OEE Calculation and Monitoring

How Waste is Defined in Manufacturing

Merging OEE Monitoring and ISO 50001

Lean Continuous Improvement – Key to Success in Any Industry

Improve your OEE: Switch From Reactive to Predictive Maintenance

Knowledge Base

Why oee has become the gold standard for manufacturing

22, November 2022OEE is a key performance indicator that companies can use to measure their overall effectiveness. In this article, we go into the details of how OEE works and why manufacturing leaders should be using it to track progress and improve efficiency. Why Is OEE The Best Metric For Manufacturing Improvement?

Find Out More

Three keys to improving production quality in manufacturing facilities

22, November 2022A simple statement will surely affect the way you see your business improve, and here it is: as the quality of your production rises, your costs get lower. This is based off of an even simpler concept – making sure production runs the way it’s meant to will lower the...

Find Out More

The 7 Green Wastes and How to Reduce Them

22, November 2022This article explains how the Green manufacturing framework that helps manufacturers become sustainable is applied in real life. What Are the 7 Green Wastes? Energy Here we refer energy to electricity and fuels that we use for powering electrical and mechanical devices...

Find Out More

Find Yourself In Great Company

Compare Products

See How Our Solutions Can Help You

A Tipteh automation specialist is waiting for your call. Find out how our software can help your business improve in efficiency.