The blog aims to show you how to calculate OEE and its components properly, using formulas and calculation examples. The three formulas that we are going to examine are:

1. Availability Formula 2. Performance Formula 3. Quality Formula.

Availability Formula

Availability of OEE is simply the proportion of the scheduled working hours that your equipment is really operating.

Calculating equipment/machine availability, the actual working time is divided by all scheduled time for the same period to obtain the proportion, which is then multiplied by 100 to express the value in percentages.

You set your scheduled working time, but to calculate actual working time, you simply subtract all stops from your scheduled working time.

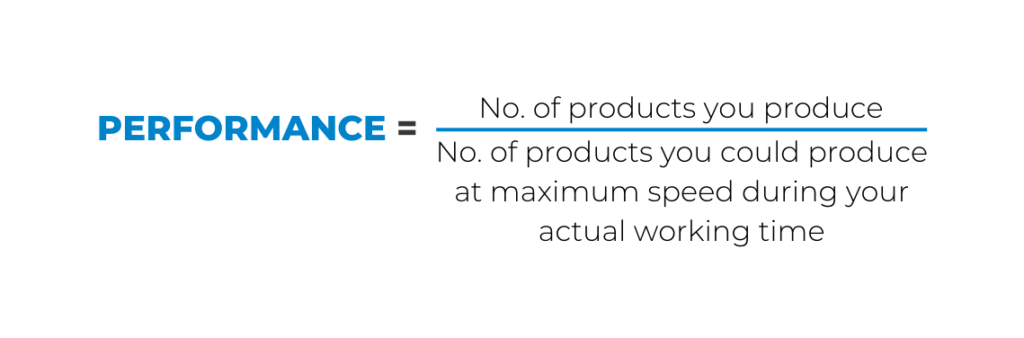

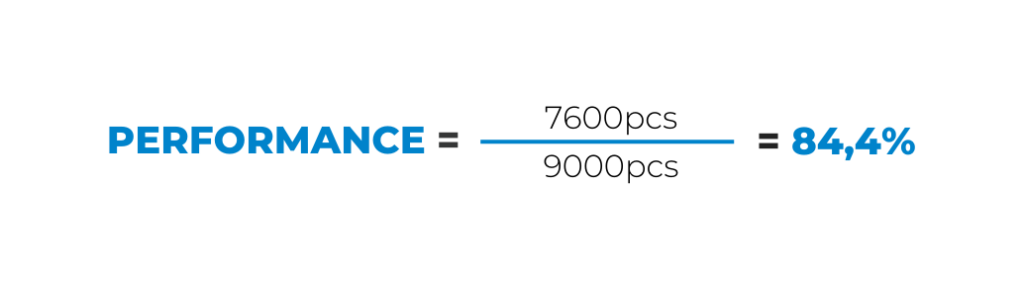

Performance Formula

Performance is calculated by comparing how many products you really produce to the number of products you can produce at maximum speed during actual working time. To find out how many products you could produce, simply multiply actual working time with maximum production speed. And you find your maximum production speed by examining past performance, and finding your fastest record time, then you assume how many products would you produce if your actual speed was on that speed all the time.

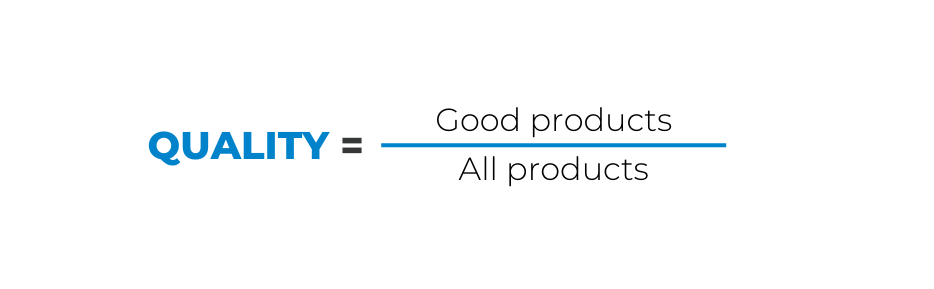

Quality Formula

Quality is calculated in a way that shows the portion of good products among all products that you produce. Where all products are the sum of good products, scrapped and reworkable products.

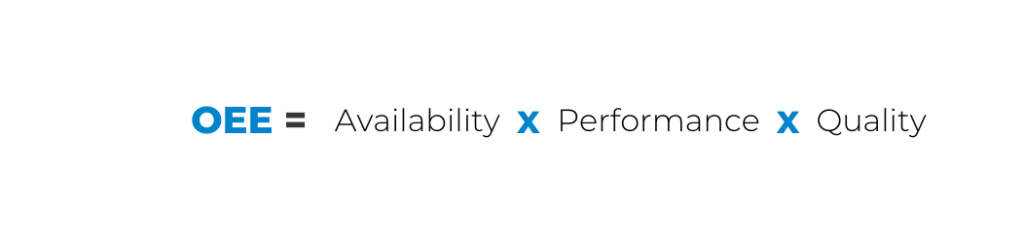

OEE Calculation Formula

In the end, to calculate the total OEE, we need to combine these three formulas. It is simply a multiplication of components. There are some simpler ways for calculating OEE, but this formula is the best when you need to calculate one of the missing components.